The next step is to solder the pieces together using a gas blowtorch – or two at the same time if it’s a big job – to melt the solder. A lot of heat is needed to melt precious metal solder. Not far below the melting temperature of the metal itrself. To ensure that they do not contaminate the metal they need to be of the same carat or grade as the metals you are joining. A great deal of patience is needed for this part of the process. It’s probably the part that takes the most swearing!! Solder has a habit of pinging off as you heat it up as the flux reacts, or flows completely the wrong way when it does melt! Fortunately most customers are blissfully unawate of this part of the process…

The next step is to solder the pieces together using a gas blowtorch – or two at the same time if it’s a big job – to melt the solder. A lot of heat is needed to melt precious metal solder. Not far below the melting temperature of the metal itrself. To ensure that they do not contaminate the metal they need to be of the same carat or grade as the metals you are joining. A great deal of patience is needed for this part of the process. It’s probably the part that takes the most swearing!! Solder has a habit of pinging off as you heat it up as the flux reacts, or flows completely the wrong way when it does melt! Fortunately most customers are blissfully unawate of this part of the process…

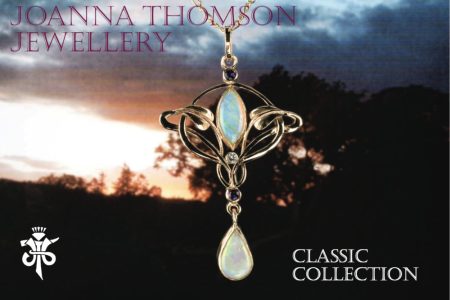

I love seeing how my designs emerge as I build them up, adding shapes and connecting wires until I am happy with the flow and balance of the design. Settings need to be made and soldered into place.